More

What are the benefits of blow molded plastic tables and chairs

What are the benefits of blow molded plastic tables and chairs

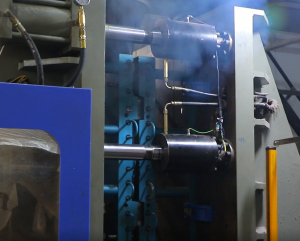

In the previous article, we introduced WHAT IS THE PRODUCTION PROCESS FOR PLASTIC TABLES AND CHAIRS. Today we will introduce to you in more detail the most important step in the production process of Aicathlon plastic tables and chairs, “blow molding”.

What is blow-molded?

Blow molding is a manufacturing process used to produce hollow plastic parts by inflating a molten tube of plastic material until it fills a mold and forms the desired shape. The process involves several steps, including heating plastic material to a molten state, forming it into a tube or parison, inflating the parison in a mold to the desired shape, and then cooling the plastic until it solidifies and can be removed from the mold.

Blow molding is used to produce a wide range of plastic products, including containers, bottles, pipes, and large parts such as tanks, playground equipment, and outdoor furniture like tables and chairs. The process is ideal for producing large, hollow parts with a uniform wall thickness and a smooth, consistent surface.

There are several different types of blow molding, including extrusion blow molding, injection blow molding, and blow molding using a blow molding machine. Each type of blow molding has its own set of advantages and disadvantages, and the choice of method will depend on the desired end product and the specific requirements of the manufacturer.

What is the production process of blow-molded plastic tables and chairs?

The process can be broken down into several basic steps:

Melting and Extrusion: The plastic material, typically PE, PP, HDPE or a blend of these materials, is melted and mixed together to create the desired plastic formulation.

The melted plastic is then fed into an extruder, which pushes it through a die and forms it into a continuous parison or tube.

Mold Closure: The parison is then transferred to a mold, which is usually made of metal. The mold is closed, and the parison is held in place by clamping or vacuum systems.

Inflation: Air is then blown into the parison, which pushes it against the mold walls and forms it into the desired shape. The pressure of the air and the pressure applied by the mold walls help to ensure that the plastic material fills the mold completely and forms a uniform wall thickness.

Cooling: Once the plastic has been inflated to the desired shape, it is cooled until it solidifies and can be removed from the mold. The cooling process is usually achieved using fans or water-cooled coils.

Trimming and Finishing: Once the part has cooled and solidified, it is removed from the mold and any excess material is trimmed away. The part is then sanded and polished to remove any surface defects and create a smooth, attractive finish.

Assembly: If the table or chair is a multi-piece product, the individual parts are then assembled to form the final product.

Quality Control: Finally, the completed product is subject to a series of quality control checks to ensure that it meets the desired specifications and standards. Any parts that do not meet these standards are rejected and recycled.

Blow molding is a highly efficient and cost-effective process that allows manufacturers to produce large quantities of high-quality, consistent plastic parts with a minimum of waste. The process can be automated, with robots handling many of the tasks, such as transferring the parison to the mold, trimming the excess material, and quality control, making it ideal for high-volume production runs.

Blow molded plastic tables and chairs have several benefits, including:

Durability: Blow molded plastic is a strong and durable material that can withstand heavy use and resist damage from impact, weather, and UV rays. This makes blow molded furniture ideal for outdoor use, as well as for commercial settings where the furniture will be subjected to frequent use and handling.

Lightweight: Blow molded plastic furniture is lightweight, making it easy to move around and arrange. This is particularly useful for outdoor settings, where furniture may need to be moved to accommodate changing needs or to clear a space for other uses.

Low Maintenance: Unlike wood or metal furniture, blow molded plastic furniture is easy to clean and maintain. It can be wiped down with soap and water, or hosed off, to keep it looking new and fresh.

Cost-Effective: Blow molded plastic furniture is less expensive than many other types of furniture, making it a cost-effective option for those on a budget. This can be especially beneficial for commercial settings, where purchasing large quantities of furniture is required.

Design Flexibility: Blow molded plastic can be molded into a variety of shapes and sizes, which means that designers have more freedom to create unique and attractive pieces of furniture.

Recyclable: Blow molded plastic is recyclable, which means that it can be reused or repurposed after its useful life has ended, reducing waste and helping to protect the environment.

Overall, blow molded plastic tables and chairs offer a combination of durability, low maintenance, cost-effectiveness, design flexibility, and environmental sustainability, making them an attractive choice for a wide range of applications.