More

Ai-Cathlon Precision Engineering Manufacturing Process

Ai-Cathlon Precision Engineering Manufacturing Process

At Ai-Cathlon, our factory’s controlled process is what sets our commercial-grade plastic folding tables and chairs apart. For B2B suppliers and procurement managers, here is a transparent look at how we build durability and value into every product.

Core Production Workflow

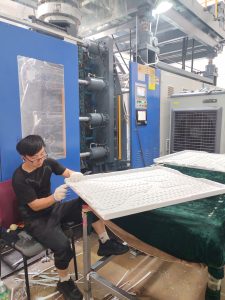

Blow Molding

We shape high-impact plastic into seamless, hollow shells. This creates a structure that is both lightweight and exceptionally robust—a key advantage for a folding furniture manufacturer.

Cutting & Punching

Components are trimmed for clean edges. Precision holes are punched for assembly, ensuring consistency across all parts.

Polishing & Powder Coating

Surfaces are smoothed for optimal finish. Metal frames receive a tough, electrostatic powder coat, providing superior resistance to scratches and corrosion—a mark of commercial quality.

Riveting & Assembling

We use high-strength riveting for permanent, reliable joints at critical stress points. The final assembling creates a stable and safe folding mechanism.

Inspecting & Packaging

Every unit undergoes a final inspecting for function and finish. We then use secure packaging to ensure products arrive in pristine condition, ready for container loading and shipment.

Your Reliable Manufacturing Partner

AI-Cathlon combines advanced engineering with rigorous checks. As a direct factory, we control quality at every step to deliver furniture that performs. Partner with us for products built to last.